Supply Chain Bullwhip Effect

The COVID-19 pandemic has highlighted very clearly some underlying human traits we continue to be blind to, at least in my opinion. The one behaviour in clear focus, at least as I see it, is the level of fear that is generated in the general population each time a lockdown is announced. For me this is staggering. The first thing we see when a lockdown is announced is the sudden rush to go shopping at supermarkets. When the Queensland Government announced the three day lockdown recently I had literally stepped foot into a client’s reception area, so it was around 8:30am or a bit before. By the time I had a break to grab a coffee at 10:30 my Facebook page had images of my local Woolworths at Newstead with a line that went out of the shopping centre, and snaked down the street for two blocks. This is despite the fact the lockdown was for only three days and the supermarkets had proven that, within reasonable demand levels, their supply chains were able to cope.

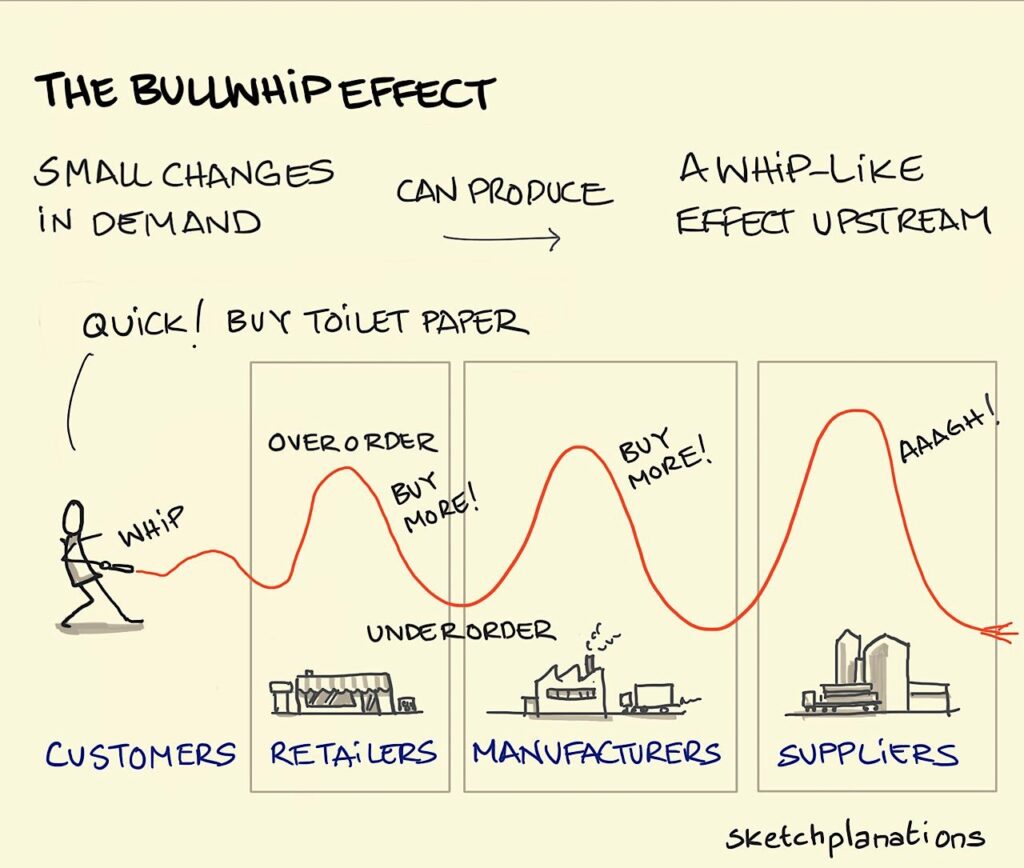

Why do their shelves suddenly become empty? They suffer from a condition called the bullwhip effect – so called because a small shift at one end of the whip creates massive movement causing the loud sound that cracks the sound barrier at the other. How this applies to products is eloquently represented in the image below.

The fact supermarkets and their manufacturing partners can respond so quickly is a testament to the work that has been done over the past couple of decades. If this event had happened in the 1970s, there is no way the supply of these goods would be as resilient and return to normal as quickly as they have currently. This level of resilience is the product of a lot of investment in equipment, efficient warehousing and logistic capabilities, technology systems along with sophisticated forecasting and collaboration tools. However the thing I have learnt over my 30 years consulting is not everyone is as good at this as the supermarkets are. In fact there are many smaller supplier to supermarkets, and others, that are woefully prepared for what it takes to be good at this. If you want to be good at this you need, at a minimum, the following:

- A recently devised strategy, that is within the last three months. COVID-19 has clearly identified yesterday’s strategy does not work in today’s environment. Even if you are two years into a five year strategy, it is out of date and is not serving you properly.

- A full understanding of my 5V supply chain model, which you can see here.

- Have very good inventory control behaviours where you have good visibility, solid velocity and you understand the vulnerability of your inventory. Many organisations have very poor inventory management practices. I am astounded by how many companies continue to count their inventory for end of year financial purposes only. They clearly do not understand the power or competitive advantage great inventory management behaviours bring to the table.

- Have information systems that provide great visibility and velocity of information on operations and within your extended supply chain. ERP and other technology solutions can be a great enabler. Unfortunately more often than not technology is deployed for the sale of technology not to bring a competitive advantage to the business. Even those utilising modern applications are, more often than not, not taking a strategic approach to technology investment. It tends to be an ad hoc buy something we find type of approach.

- Sound relationships internally and externally with suppliers. Culture has a major impact on performance. Your internal culture, and that of your suppliers, will have significant influence on the performance of how material, information and money flows through your supply chain. Understanding this is critical to having a resilient supply chain.

- An ability to collaborate with suppliers, particularly around innovation. What innovative ideas are they bringing to you? How are they helping you stay at the forefront of your industry? What information are you sharing with them to help you both manage the bullwhip effect?

There is more to a resilient supply chain than managing the bullwhip effect. However if you use it as a starting point, it stands you in great stead to springboard onto greater success.

If you or anyone you know is looking to:

- improve the way their business operates;

- improve the way they leverage their current ERP system;

- replace their ERP current system;

give me a call for a confidential discussion on the best way to achieve this.

Until next month…

Sincerely,

David